Five questions for … 3D printing expert Bernard Meade

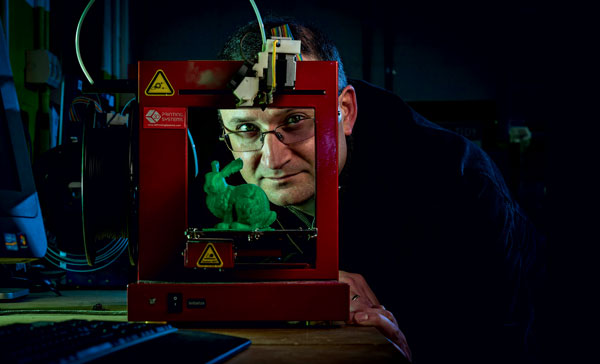

Amazing potential: Bernard Meade in the University’s 3D workshop. Picture: Chris Hopkins

It’s the stuff of science fiction: printers that can create not just plastic or metal objects, but food and even body parts. Bernard Meade (BA, BSc 1996), organiser of the University’s annual 3D printing showcase, explains how this technology will change how we live. Val McFarlane reports.

What exactly is 3D printing and how does it work?

3D printing is another term for additive manufacturing, which in some ways is more descriptive. To get a good idea of how it works, imagine a piece of paper that you put through the printer, and you print words on it. You then put the same piece of paper through the printer again and again. The toner starts to build up in the same places and you eventually end up with something in three dimensions.

A lot of traditional manufacturing is what we might now think of as subtractive manufacturing. For example, when you create a wooden chair you have to have a piece of wood that’s bigger than each component. You take away the parts that you don’t want and what you are left with is the product. With 3D printing you add only what you need, and you can manage the structural integrity of a product much better than with traditional techniques. It’s incredibly efficient.

Engineers from the University were involved in the creation of a 3D printed jaw joint this year (see below). What other medical uses might 3D printing have?

It was thought we’d never be able to print living tissue, that we’d never print an organ, but researchers have been able to print out tiny livers that live for about 40 days – long enough to do specific drug testing. They’ve even printed a small heart – just a few cells – but they can make it beat. That’s a really big step. A company in China is actively working with printing bone material, and cosmetics companies are using printed skin to test for reactions.

Immediately after they publicised the operation, the Melbourne company that produced the titanium jaw joint got an order for 25 more. And that’s just a jaw – the same process will be applicable to pretty much any other bone. Eventually a patient will be able to have a cancerous bone cut out, and a replacement printed and put straight in, in only a few hours, instead of in two or three surgeries lasting much longer.

A US defence research organisation is looking at doing MRI scans of soldiers, and separating out the scans of each part of the body. The hope is that in the future, if one of the soldiers is injured in battle, they can print out the replacement part they need to help them.

What about other uses?

In defence, there’s a design for an aeroplane with a 3D printer inside that can print drones as required. They will be programmed to self-destruct so they will fly, do their job and then the inside will disintegrate, leaving no useable components behind.

When astronauts on the International Space Station needed to fix something last year, they printed a tool out, using a design emailed to them from earth, and it did the job that they wanted it to do more effectively than the toolset they had. This is exciting because as you can imagine, the toolkit on the ISS has to be enormous. With 3D printing, they can just print out what they need then recycle it.

There’s even a printer being developed by NASA and others that will print food for astronauts, and it could be that eventually you will be able to print your food at home. When we eat, a fair amount of the experience comes from the appearance and smell of the meal. A 3D printer can replicate a lot of those things and we know it works – a trial was carried out in an aged care facility where the residents had to have soft food, which looked unappealing. They printed out food that looked like steak and broccoli, and it was much more enjoyable.

Ninety-nine per cent of the Smithsonian’s collections are not available to the public because they are so precious. The museum is now going through those artefacts and printing them so that public can enjoy them.

3D printing has the potential to impact on so many things – it’s probably easier to identify the industries on which it will have little impact.

Will we all have 3D printers at home in the future?

I think it will be similar to how we use 2D printers at the moment. Most of us have a 2D printer at home but if we wanted something professionally done we would send it to a professional printer.

It could also change the way we shop. At the moment, if you need to buy a bracket from a hardware store, for example, you pick from a standard set of sizes, and the store has to have a whole inventory available for purchase. It’s possible that in future you will go into the store, order the bracket you want from a catalogue and print it out.

It’s going to change education too. Engineers will spend less time trying to perfect a design on paper or in a computer and more time developing prototypes. Medical students won’t necessarily have to learn their anatomy on cadavers – they will have a 3D printed version of the body.

In the beginning 3D printing was very expensive. Now you can buy a printer for $500. A kid in the US built one using Lego. Most of us will want something more robust but it shows that the development is really active. There are so many people working in this space and it’s not limited to engineers, universities, big businesses – it’s anybody.

Is there a downside to 3D printing?

The fear of people printing guns is played on a lot, particularly here in Australia. But people can get guns already with a licence, and you can already make a gun without having a licence. But even though people can make guns, they typically don’t. Ultimately 3D printing allows clever people to overcome obstacles and if you are trying to overcome the obstacle of making a better gun you’ll figure it out.

Some people might choose to replace certain bones with titanium, for example, because imagine how hard you could hit if you had a fully metal arm. Or if you could put titanium flakes throughout your skin – you would be almost bulletproof. There is also always the risk that we will think we can fix things when they don’t need fixing. It could exacerbate body dysmorphia problems.

Ultimately there is real benefit to 3D printing but there has to be some wisdom applied to the way we use it.

3D printing technology on show

University of Melbourne alumni are at the forefront of developments in 3D printing medical technology.

This year Dr David Ackland (BE(Mech&ManufEng)(Hons), BSc 2003, PhD 2009, GCertUniTeach 2014) led the engineering design and testing of a titanium jaw joint implanted to correct a patient’s rare congenital jaw deformity. Dr Ackland is a senior lecturer and researcher in experimental muscle and joint biomechanics at the University of Melbourne.

And in 2014 a team including St Vincent’s Hospital surgeon Professor Peter Choong (MB BS 1984, MD 1993) implanted a titanium-printed heel bone into a man whose own bone was cancerous. Without it, the patient would have had to have his leg amputated below the knee.

Dr Ackland and Professor Choong will be among speakers at the University’s 3D printing showcase, to be held at Parkville campus on October 9 and 10 2015. The event is aimed at everyone f

rom school students to researchers and aims to highlight the potential of 3D printing.

More information on the showcase